-

Analysis of the principle of energy saving of central air conditioners

Release time:2019-09-06 | Source:HUA LI JI DIAN.Analysis of the principle of energy conservation

1、The principle of power saving can be seen by the principle of the pump of the fluid transmission equipment: the flow rate of the pump is proportional to its speed, the pressure of the pump (the pressure) is proportional to the square of its speed, and the shaft power of the pump is equal to the product of the flow and pressure, so the shaft power of the pump is three times the power of its speed. According to the above principle, it can be seen that changing the speed of the pump can change the output power of the pump. For example: if the power supply frequency is reduced from 50Hz to 45Hz, then P45\/P50 x 453\/503 x 0.729, i.e. P45 s 0.729P50 (P is the motor shaft power); 0.512P50 (P is motor shaft power)

2、The principle of freezing and cooling cycle saving power Is now qualitative analysis of the principle of power saving of refrigeration and cooling cycle system. It is assumed that a circulating water pump is changed to variable frequency control, the average flow rate is 0.8;Power-saving rate ( W original - W power-saving) \/ W original x 100% s (1-W power-saving \/ W original) x 100% W - P x T; ? ?Power-saving rate(1- P Power-saving/P Originally) ×100% =[1-(n Power-saving/n-Originally)3]×100% =[1-(0.8)3]×100% =48.8%≈49%; ?(Note: W: Work, i.e. the power consumed by the pump; P: power; T: time; Q: flow; H: head; n: speed; K 1: coefficient; K 2: coefficient K 0: coefficient)

Effect analysis

1、The original unit of the motor will appear a large impact current, the use of energy-saving system control, can make the motor start ingress with current rise flatly, without any impact;?With the use of variable frequency control, the motor can be soft stop, to avoid the damage caused by regenerative current, is conducive to extending the service life of the equipment.

2、This energy-saving control system system adopts the energy-saving system equipment of Sweden's REGIN Swiss, combined with the non-differentiated software identification of hardware operation, and no need to configure the refrigeration pump, cooling water pump, cooling tower fan, valve control box and other control equipment.

3、Save your unit machine room workers labor intensity, due to the high level of automation, there is no need to configure the central air-conditioning room for the building control system. The energy-saving system can realize the modern computer control of the central air-conditioning system, achieve the unattended effect, realize the automatic energy-efficient operation of the central air-conditioning system, and facilitate the seamless connection with the building control system.

4、With the REGIN Ruijing energy saving control system, the circulation speed of water can be controlled according to the temperature signal feedback from the temperature sensor, so as to carry out accurate temperature control. Without the need for a separate hydraulic balancing system, the air conditioning refrigerant flow can be dynamically adjusted as the load changes.

5、Circulating water system with valves to adjust the speed of water circulation, when the valve closed hours, circulation of water when the resistance increases, waste a lot of electrical energy.?With the use of variable frequency control system, the valve can be opened, by adjusting the speed of the motor to adjust the speed of water circulation, saving a lot of electrical energy.

6、to greatly reduce the noise when the motor is running and to save the amount of steam during operation.?As can be seen from the above, when the flow (air volume) control is carried out with the energy-saving system, a large amount of power can be saved. Refrigeration, cooling circulation system in the design is in accordance with the maximum demand on-site consideration, the pump according to the maximum operating conditions of a single equipment to consider, in the actual use of more than 95% of the time cycle pump are working in the non-full load state.The use of valve adjustment not only increases the system cycle pressure and throttle loss, but also causes the whole heating system to work in a fluctuating state due to the regulation of the cycle, while the installation of the variable frequency control system can solve the problem once and for all, and can also achieve automatic control and recover the investment through energy saving. At the same time, the soft start function and smooth speed control characteristics of the inverter can realize the smooth adjustment of the system, so that the system work condition is stable, and extend the service life of the unit and pipe network.

7、The energy saving effect is remarkable: the whole unit system is more than 28% energy saving.Relevant information

Top Categories in Cassette Fan coil unit types-KM

-

Water chilled Ceiling concealed 8 way Cassette Fan coil unit 300CFM -(FP-51KM)

Detailed Product DescriptionWater chilled Cassette Fan coil units KM s...

-

Water chilled Ceiling concealed 8 way Cassette Fan coil unit 400CFM -(FP-68KM)

Detailed Product DescriptionWater chilled Cassette Fan coil units KM s...

-

Water chilled Ceiling concealed 8 way Cassette Fan coil unit 500CFM -(FP-85KM)

Detailed Product DescriptionWater chilled Cassette Fan coil units KM s...

-

Water chilled Ceiling concealed 8 way Cassette Fan coil unit 500CFM -(FP-85KM)

Detailed Product DescriptionWater chilled Cassette Fan coil units KM s...

All Categories

- Water chilled Ceiling concealed 8 way Cassette Fan coil unit 300CFM -(...

- Water chilled Ceiling concealed 8 way Cassette Fan coil unit 400CFM -(...

- Water chilled Ceiling concealed 8 way Cassette Fan coil unit 500CFM -(...

- Water chilled Ceiling concealed 8 way Cassette Fan coil unit 500CFM -(...

- fan coil unit type-Cassette 800CFM -(FP-136KM)

- Water fan coil-(FP-170KM)

- Water chilled Ceiling concealed 8 way Cassette Fan coil unit 1200CFM -...

Top Categories in VRF Air conditioner-ODU

-

fabrica de China acondicionador de aire VRF | inversor de CC Fuera de unidades de puerta tipo modular| 168kw /60HP

Proveedor de China de acondicionador de aire VRF | inversor de CC Fuer...

-

fabrica de China de acondicionador de aire VRF | inversor de CC Fuera de unidades de puerta tipo modular|34HP 95KW

Proveedor de China de acondicionador de aire VRF | inversor de CC Fuer...

-

fabrica de China acondicionador de aire VRF | inversor de CC Fuera de unidades de puerta tipo modular| 184.5kw /66HP

Proveedor de China de acondicionador de aire VRF | inversor de CC Fuer...

-

fabrica de China acondicionador de aire VRF | inversor de CC Fuera de unidades de puerta tipo modular| 146.5kw /52HP

Proveedor de China de acondicionador de aire VRF | inversor de CC Fuer...

All Categories

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- VRF DC INVERTER AIR CONDITIONER Out door units

- VRF system with HITACHI compressor(DRV-56)

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- Proveedor de China de acondicionador de aire VRF | inversor de CC Fuer...

- Proveedor de China de acondicionador de aire VRF | inversor de CC Fuer...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

Top Categories in VRF Air conditioner-IDU

-

China good quality VRF Unit factory| ceiling cassette type indoor unit | 16KW| 360° round way flow air outlet

DEKON VRF air conditioner China good quality VRF Factory for years.Dek...

-

VRF system indoor unit cassette type

Detailed Product DescriptionVRF air conditioner,with below features:1....

-

VRF system indoor unit wall type

Detailed Product DescriptionVRF air conditioner,with below features:1....

-

VRF system indoor unit ceiling concealed high pressure type

Detailed Product DescriptionDEKON VRF air conditioner,with below featu...

All Categories

- China good quality VRF Unit factory| ceiling cassette type indoor unit...

- VRF system indoor unit cassette type

- VRF system indoor unit wall type

- VRF system indoor unit ceiling concealed high pressure type

- VRF system indoor unit ceiling concealed mid pressure type

- VRF Air conditioner indoor unit ceiling floor type

- VRF Air conditioner indoor unit cassette type

- VRF air conditioner indoor unit ceiling floor type

- VRF Air conditioner indoor unit ceiling concealed type

- VRF air conditioner indoor unit ceiling floor type

- VRF air conditioner indoor unit ceiling concealed high pressure type

- VRF air conditioner indoor unit ceiling concealed slim design

- VRF air conditioner indoor unit cassette type

- VRF AIR CONDITIONER Out door units DC INVERTER technology

- VRF AIR CONDITIONER Out door units DC INVERTER technology

- EOT crane E house fitted High temperature AC

- VRF air conditioner indoor unit wall type

- VRF air conditioner cassette type indoor unit 2.8KW 360° air outlet ro...

- Dekon VRF air conditioner cassette type indoor unit 3.6KW 360° air out...

- Dekon VRF air conditioner cassette type indoor unit 4.5KW 360° air out...

- Dekon VRF air conditioner cassette type indoor unit 5.0KW 360° air out...

- Dekon VRF air conditioner cassette type indoor unit 5.6KW 360° air out...

- Dekon VRF air conditioner cassette type indoor unit 6.3KW 360° air out...

- China good quality VRF air conditioner|cassette type indoor unit | 240...

- China good quality VRF air conditioner supplier|cassette type indoor u...

- China good quality VRF air conditioner factory|cassette type indoor un...

- China good quality VRF Unit factory|cassette type indoor unit | 11.2KW...

- China good quality VRF Unit factory|cassette type indoor unit | 11.2KW...

Top Categories in Air cooled Chiller system

-

Air cooled water chiller screw type

Detailed Product Description unit style CMA200DNCooling capacitykW700I...

-

Air cooled chiller modular type with heat pump-20TR

Air cooled chiller modular chiller-20TRThe unit shell is made of galva...

-

Air cooled chiller modular type with heat pump-20TR

Air cooled chiller modular chiller-20TRThe unit shell is made of galva...

-

Air cooled chiller modular type with 122kw capacity-35TR scroll chiller

Detailed Product DescriptionAir cooled chiller modular type with 122kw...

All Categories

- Air cooled water chiller screw type

- Air cooled chiller modular type with heat pump-20TR

- Air cooled chiller modular type with heat pump-20TR

- Air cooled chiller modular type with 122kw capacity-35TR scroll chille...

- Air cooled screw chiller 200TR with heat pump optional(CMA200DN)

- Air cooled chiller screw type 200TR with heat pump (CMA200DN)

- Air cooled screw chiller 700KW with heat pump

- Air cooled chiller modular type with heat pump-40TR

- Air cooled screw chiller 1500KW-with heat pump optional

- Air cooled screw chiller 1120KW-with heat pump optional

- Air cooled screw chiller 930KW-with heat pump optional

- Air cooled screw chiller 840KW-with heat pump optional

- Air cooled screw chiller 560KW-with heat pump optional

- Air cooled screw chiller 740KW-with heat pump optional

- Air cooled screw chiller 370KW-with heat pump optional

- Air cooled screw chiller 700KW with heat pump

- Air cooled screw chiller 150TR

- Air cooled chiller screw type 200TR with heat pump (CMA200DN)

- Air cooled chiller screw type 100TR with R134a gas

- High efficiency screw compressor heat pump chiller

- R22 gas Air cooled chiller screw type 390TR with heat pump ASWC-HC390

- Air cooled heat pump-40TR

- Air cooled chiller modular chiller

- Air cooled chiller modular type with 122kw capacity- 122x4=130TR scrol...

- Air cooled screw chiller 200TR with R134A Gas

- Air cooled chiller modular chiller

- Bitzar compressor Air cooled screw chiller

- Bitzar compressor Air cooled screw chiller

Top Categories in Water cooled chiller system

-

Centrifugal water cooled chiller

Detailed Product Description LC Centrifugal water chiller:LC series of...

-

Water cooled chiller Centrifugal type for Nuclear Power Station

Detailed Product Description LC Centrifugal water chiller:LC series of...

-

Centrifugal Water cooled chiller

Detailed Product Description Water-cooled Screw Chiller Refrigerant: R...

-

Water cooled chiller Centrifugal type for Nuclear Power Station

Detailed Product Description LC Centrifugal water chiller:LC series of...

All Categories

- Centrifugal water cooled chiller

- Water cooled chiller Centrifugal type for Nuclear Power Station

- Centrifugal Water cooled chiller

- Water cooled chiller Centrifugal type for Nuclear Power Station

- Water cooled screw chiller

- low temperature Centrifugal water cooled chiller

- Centrifugal water chiller-twin compressor

- Twin compressor Centrifugal water chiller

- Centrifugal Chiller for Nuclear Power Station

- Centrifugal water Chiller for Nuclear Power Station

- Centrifugal water chiller

- Centrifugal water chille

- Twin compressor Centrifugal water cooled chiller

- Centrifugal water cooled chiller Twin compressor

- Centrifugal water cooled chiller

- Centrifugal water cooled Chiller for Nuclear Power Station

- Centrifugal water cooled Chiller for Nuclear Power Station

- Twin compressor Centrifugal water chiller

- Centrifugal water Chiller for Nuclear Power Station

- Centrifugal water Chiller for Nuclear Power Station

- Centrifugal water chiller

- Centrifugal water chiller Twin compressor

- Twin compressor Centrifugal water chiller

- Centrifugal Water chiller

- Twin compressor Centrifugal chiller

- Centrifugal water Chiller for Nuclear Power Station

- Centrifugal water Chiller for Nuclear Power Station

- Centrifugal water Chiller 2000TR capacity for T3 conditions

Top Categories in Cassette Fan coil unit types-E

-

Water chilled ceiling concealed Cassette Fan coil units 2 tubes 1200CFM-(FP-204CA-E)

Detailed Product Description model(2 tube system)FP-102CA-EFP-136CA-EF...

-

Water chilled ceiling concealed Cassette Fan coil units 2 tubes 1400CFM-(FP-238CA-E)

Detailed Product Description model(2 tube system)FP-102CA-EFP-136CA-EF...

-

Water chilled ceiling concealed Cassette Fan coil units 2 tubes 200CFM-(FP-34CA-E)

Detailed Product Description model(2 tube system)FP-34CA-EFP-51CA-EFP-...

-

Water chilled ceiling concealed Cassette Fan coil units 2 tubes 300CFM-(FP-51CA-E)

Detailed Product Description model(2 tube system)FP-34CA-EFP-51CA-EFP-...

All Categories

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 1200CF...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 1400CF...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 200CFM...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 300CFM...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 400CFM...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 500CFM...

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 200CFM...

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 300CFM...

- Fan coil unit type-cassette water fan coil(FP-68CA-E4)

- fan coil unit type-cassette four ways(FP-85CA-E4)c

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 800CFM...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 800CFM...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 1000CF...

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 600CFM...

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 1000CF...

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 1200CF...

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 1400CF...

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 1400CF...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 600CFM...

Top Categories in Cassette Fan coil unit types-K

-

Four Way Cassette Type Fan Coil with DC Motor (FP-204CA/4KD)

Detailed Product DescriptionApplication:CommercialType:Fan Coil UnitFo...

-

Four Way Cassette Type Fan Coil with DC Motor (FP-238CA/4KD)

Detailed Product DescriptionApplication:CommercialType:Fan Coil UnitFo...

-

Four Way Cassette Type Fan Coil with DC Motor (FP-102CA/4KD)

Detailed Product DescriptionApplication:CommercialType:Fan Coil UnitFo...

-

DC Motor Four Way Cassette Fan Coil units(FP-85CA/4KD)

Detailed Product DescriptionApplication:CommercialType:Fan Coil UnitFo...

All Categories

- Four Way Cassette Type Fan Coil with DC Motor (FP-204CA/4KD)

- Four Way Cassette Type Fan Coil with DC Motor (FP-238CA/4KD)

- Four Way Cassette Type Fan Coil with DC Motor (FP-102CA/4KD)

- DC Motor Four Way Cassette Fan Coil units(FP-85CA/4KD)

- DC Motor Four Way Cassette Fan Coil units(FP-68CA/4KD)

- DC Motor Four Way Cassette Fan Coil units(FP-51CA/4KD)

- DC Motor Cassette Fan Coil units(FP-34CA/KD)

- DC Motor Cassette Fan Coil units(FP-51CA/KD)

- DC Motor Cassette Fan Coil units(FP-68CA/KD)

- DC Motor Cassette Fan Coil units(FP-85CA/KD)

- DC Motor four way Cassette Fan Coil units(FP-102CA/KD)

- DC Motor four way Cassette Fan Coil units(FP-136CA/KD)

- DC Motor four way Cassette Fan Coil units(FP-170CA/KD)

- DC Motor four way Cassette Fan Coil units(FP-204CA/KD)

Top Categories in Ceiling concealed-fan coil unit types

-

Ceiling concealed duct fan coil unit

Detailed Product DescriptionType:Central Air ConditionersCooling/Heati...

-

Ceiling concealed duct fan coil unit- 340CFM (2 tubes)

Detailed Product DescriptionType:Central Air ConditionersCooling/Heati...

-

Ceiling concealed duct fan coil unit- 510CFM (2 tubes)

Detailed Product DescriptionCooling/Heating:Cooling/HeatingCeiling con...

-

Ceiling concealed duct fan coil uint-680CFM (2 tubes)

Detailed Product DescriptionCooling/Heating:Cooling/HeatingCeiling con...

All Categories

- Ceiling concealed duct fan coil unit

- Ceiling concealed duct fan coil unit- 340CFM (2 tubes)

- Ceiling concealed duct fan coil unit- 510CFM (2 tubes)

- Ceiling concealed duct fan coil uint-680CFM (2 tubes)

- Ceiling concealed duct fan coil uint-680CFM (2 tubes)

- Ceiling concealed duct fan coil unit-850 CFM (2-TUBES)

- Ceiling concealed duct fan coil unit- 1020 CFM ( 2 tubes)

- Ceiling concealed duct fan coil unit-1360CFM (2 TUBES)

- Ceiling concealed duct fan coil unit- 1700CFM (2 TUBES)

- Ceiling concealed duct fan coil unit-2040CFM (2 TUBES)

- Ceiling concealed duct fan coil unit-2380CFM ( 2 tubes)

- Ceiling concealed duct fan coil unit-340CFM (4 tubes)

- Ceiling concealed duct fan coil unit-510CFM ( 4 tubes)

- Ceiling concealed duct fan coil unit-680CFM (4 tubes)

- Ceiling concealed duct fan coil unit-850 CFM (4 tubes)

- Ceiling concealed duct fan coil unit-1020CFM (4 tubes)

- Ceiling concealed duct fan coil-1360CFM (4 tubes)

- water fan coil-Ceiling concealed duct fan coil unit type-170CFM(4 tube...

- water fan coil-Ceiling concealed type-2040CFM (4 tubes)

- Fan Coil units with EC Motor(FP-85WA/E)

- Ceiling concealed Fan Coil units with EC Motor(FP-204WA/E)

- Ceiling concealed Fan Coil units with EC Motor(FP-238WA/E)

- Ceiling concealed Fan Coil units with EC Motor(FP-238WA/4E)

- Ceiling concealed Fan Coil units with EC Motor(FP-204WA/4E)

- EC Motor Ceiling concealed Fan Coil 4 pipe system (FP-170WA/4E)

- EC Motor Ceiling concealed Fan Coil with 4 pipe system (FP-68WA/4E)

- Fan Coil units with EC Motor 4 pipe system(FP-85WA/4E)

- Ceiling concealed Fan Coil units with EC Motor 4 pipe (FP-102WA/4E)

Top Categories in Ceiling floor fan coil unit types

-

One way cassette fan coil units-4tubes

Detailed Product DescriptionmodelFP-34O-4FP-51O-4FP-68O-4FP-85O-4power...

-

Ceiling floor type fan coil units 2 tubes 1200CFM-FP-204CF)

Detailed Product DescriptionPower (W):189Voltage (V):220Use:RoomPower ...

-

Ceiling floor type fan coil units 2 tubes 1000CFM-(FP-170CF)

Detailed Product DescriptionPower (W):152Voltage (V):220Use:RoomPower ...

-

Ceiling floor type fan coil units 2 tubes 800CFM-(FP-136CF)

Detailed Product DescriptionPower (W):134Voltage (V):220Use:RoomPower ...

All Categories

- One way cassette fan coil units-4tubes

- Ceiling floor type fan coil units 2 tubes 1200CFM-FP-204CF)

- Ceiling floor type fan coil units 2 tubes 1000CFM-(FP-170CF)

- Ceiling floor type fan coil units 2 tubes 800CFM-(FP-136CF)

- Water chilled Ceiling floor fan coil units 2 tubes 400CFM-FP-68CF

- Water chilled Ceiling floor fan coil units 2 tubes 500CFM-FP-85CF

- Water chilled Ceiling floor type fan coil units 2 tubes 1400CFM-(FP-23...

Top Categories in One way cassette fan coil unit types

-

Water chilled One way ceiling concealed cassette fan coil unit-FCU 200CFM-(FP-34O)

Detailed Product Description modelFP-34OFP-51OFP-68OFP-85Opower supply...

-

Water chilled One way ceiling concealed cassette fan coil unit-FCU 300CFM-(FP-51O)

Detailed Product Description modelFP-34OFP-51OFP-68OFP-85Opower supply...

-

Water chilled One way ceiling concealed cassette fan coil unit-FCU 400CFM-(FP-68O)

Detailed Product Description modelFP-34OFP-51OFP-68OFP-85Opower supply...

-

Water chilled One way ceiling concealed cassette fan coil unit-FCU 500CFM-(FP-68O)

Detailed Product Description modelFP-34OFP-51OFP-68OFP-85Opower supply...

All Categories

- Water chilled One way ceiling concealed cassette fan coil unit-FCU 200...

- Water chilled One way ceiling concealed cassette fan coil unit-FCU 300...

- Water chilled One way ceiling concealed cassette fan coil unit-FCU 400...

- Water chilled One way ceiling concealed cassette fan coil unit-FCU 500...

- Water chilled One way ceiling concealed cassette fan coil unit 4tube-F...

- Water chilled One way ceiling concealed cassette fan coil unit 4tube-F...

- fan coil unit type-cassette one way(FP-68O-4)

Top Categories in Universal Fan coil unit types

-

Water chilled Universal free stand type Fan coil units 1000CFM 4 TUBES-(FP-170U-4)

Detailed Product Description modelFP-102U-4FP-136U-4FP-170U-4FP-204U-4...

-

Water chilled Universal free stand type Fan coil units 1400CFM 4 TUBES-(FP-238U-4)

Detailed Product Description modelFP-102U-4FP-136U-4FP-170U-4FP-204U-4...

-

Water chilled Universal free stand type Fan coil units 1200CFM 4 TUBES-(FP-204U-4)

Detailed Product Description modelFP-102U-4FP-136U-4FP-170U-4FP-204U-4...

-

Water chilled Universal free stand type Fan coil units 800CFM 4 TUBES-(FP-136-4)

Detailed Product Description modelFP-102U-4FP-136U-4FP-170U-4FP-204U-4...

All Categories

- Water chilled Universal free stand type Fan coil units 1000CFM 4 TUBES...

- Water chilled Universal free stand type Fan coil units 1400CFM 4 TUBES...

- Water chilled Universal free stand type Fan coil units 1200CFM 4 TUBES...

- Water chilled Universal free stand type Fan coil units 800CFM 4 TUBES-...

- Water chilled Universal free stand type Fan coil units 600CFM 4 TUBES-...

- Water chilled Universal free stand type Fan coil units 300CFM-4 tubes(...

- Water chilled Universal free stand type Fan coil units 400CFM-4 tubes(...

- Water chilled Universal free stand type Fan coil units 500CFM-4 tubes(...

- Water chilled Universal free stand type Fan coil units 300CFM 2 TUBES-...

- Water chilled Universal free stand Fan coil units 400CFM 2 TUBES-(FP-6...

- Water chilled Universal free stand type Fan coil units 400CFM 2 TUBES-...

- Water chilled Universal free stand type Fan coil units 500CFM 2 TUBES-...

- Water chilled Universal stand type Fan coil units 200CFM-4 tubes(FP-34...

- Water chilled Universal stand type Fan coil units 200CFM 2 TUBES-(FP-3...

Top Categories in Wall split Fan coil unit types

-

High wall mounted type fan coil unti

Detailed Product DescriptionHigh wall fan coil unit in 2 tubes model(2...

-

Wall split type fan coil unit with valve inside

Detailed Product DescriptionHigh wall fan coil unit in 2 tubes with va...

-

water chilled high wall fan coil unit in 2 tubes

Detailed Product Descriptionwater chilled high wall fan coil unit in 2...

-

water fan coil

Detailed Product DescriptionWater fan coil- wall split typeWall split ...

All Categories

Top Categories in Light commercial A/C

-

CONSOLA PISO-TECHO Aire Acondicionado

Detailed Product Description CONSOLA PISO-TECHO AIRE ACONDICIONADO Ai...

-

CONSOLA PISO-TECHO TIPO

Detailed Product Description CONSOLA PISO-TECHO TIPO Aire Acondiciona...

-

aire acondicionado piso techo tipo

Detailed Product DescriptionUse:Aire Acondicionado Piso Techo TipoAire...

-

aire acondicionado piso techo tipo

Detailed Product DescriptionUse:Aire Acondicionado Piso TechoAire acon...

All Categories

Top Categories in Air handling Units

-

Equipos aires acondicionados de split ducto

Detailed Product DescriptionUse:Equipos Aires Acondicionados Split Duc...

-

Equipos aires acondicionados de split ducto

Detailed Product DescriptionUse:Equipos Aires AcondicionadosEquipos ai...

-

Equipos aires acondicionados de split ducto

Detailed Product DescriptionUse:Equipos Aires AcondicionadosEquipos ai...

-

Equipos aires acondicionados de split ducto

Detailed Product DescriptionUse:Equipos Aires AcondicionadosEquipos ai...

All Categories

- Equipos aires acondicionados de split ducto

- Equipos aires acondicionados de split ducto

- Equipos aires acondicionados de split ducto

- Equipos aires acondicionados de split ducto

- Equipos aires acondicionados de split ducto

- Suspendido en Techo horizontal UNIDADES MANEJADORAS DE AIRE (UMA)

- horizontal UNIDADES MANEJADORAS DE AIRE (UMA) Suspendido en Techo

- UNIDADES MANEJADORAS DE AIRE horizontal TIPO (UMA) Suspendido en Techo

- Suspendido en Techo horizontal decarga horizontal UNIDADES MANEJADORAS...

- horizontal UNIDADES MANEJADORAS DE AIRE (UMA)

- Vertical UNIDADES MANEJADORAS DE AIRE (UMA)

- Horizontal air handling units ceiling concealed type

- Modular design Air Handling Units-AHU for hospical

- Air handling units with prefilter and Hepa filter

Top Categories in Industrial Air conditioner

-

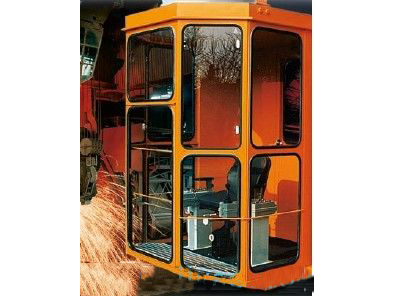

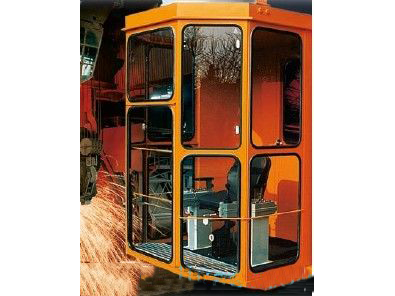

Coking plants high temperature air conditioner

Detailed Product Description In heavy industry field such as steel wor...

-

steel works high temperature air conditioner

Detailed Product Description In heavy industry field such as steel wor...

-

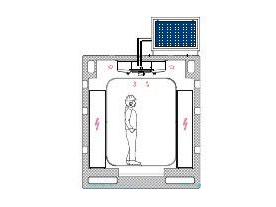

HIGH TEMPERATURE AC UNITS( AMBIENT TEMP 65C) FOR EOT CRANE APPLICATION

Detailed Product DescriptionHIGH TEMPERATURE AC UNITS( AMBIENT TEMP ...

-

HIGH TEMPERATURE Air conditioner FOR EOT CRANE APPLICATION

Detailed Product DescriptionHIGH TEMPERATURE AC UNITS( AMBIENT TEMP ...

All Categories