-

Central air conditioning installation specification (II) - construction and installation process

Release time:2019-08-20 | Source:HUA LI JI DIAN.Holes in the inner and outer walls

1, the outer wall punching

1.1. The property's consent must be obtained before punching, so as to avoid damaging the structure of the outer wall.

1.2, in order to prevent rain water pour, the angle of the wall hole should ensure an outward downward tilt. Drillers should be used when opening holes to ensure that the cut holes are as smooth and neat as possible.

1.3, the inside and outside of the hole should be used tube sleeve, to prevent the refrigerant insulation material by the hole inside the bristling of the bristles, and affect the indoor beauty.

2, the inner wall punched

2.1, because the steel structure of the general beam is around it, so indoor punching through the beam, please try to open in the middle of the beam.

2.2, before punching must obtain the property's consent to carry out.

Second, lifting indoor machine

1, indoor positioning

1.1, if the use of infrared locator can ensure that indoor machine installation efficiency, more stable.

1.2, according to the original design drawings and site conditions to adjust the actual installation position. Avoid installation as follows.

2, fixed

2.1, after the completion of positioning, the indoor machine with a full-threaded boom of 10mm fixed to the ceiling, to ensure that the internal machine lifting work unfolded.

3, double nut reinforced fixed

3.1, must use a double nut in the lower end of the screw to be fixed to ensure that the indoor machine lifting is firm. The use of a nut will cause the indoor machine to run during the process of loosening, causing noise.

4, horizontal lifting

4.1, indoor machine must ensure a horizontal installation, in order to reduce the operating noise, to ensure that the operation of air conditioning effect. Do not attach to the ceiling installation, this will cause resonance, resulting in increased noise.

4.2, indoor machine installation should pay attention to the two sides to reserve enough space, easy to access.

5, indoor protection

5.1, indoor machine lifting after the use of plastic film and other materials to the indoor machine wrapped up to prevent the interior decoration dust and odor into the interior of the indoor machine, resulting in the first use of a large amount of dust and odor blowing out and affect health, while dust accumulation on the indoor machine heat exchange fins will affect the thermal effect, resulting in a decline in operating efficiency.

Third, refrigerant distribution engineering, drainage pipe engineering, signal line engineering, power line engineering

1, refrigerant pipe ding

1.1, if the use of saws or cutters to cut copper pipe will cause the incision is not neat, horn mouth dressing is quite difficult, easy to cause refrigerant leakage, while the resulting copper chips will cause the air conditioning clogging period will even damage the air conditioning. Therefore, when cutting refrigerant piping must use professional tools - copper pipe cutter.

1.2, deburring is also quite important, such as not burrs may lead to the edge of the horn mouth folding edge, so that poor air tightness, causing refrigerant leakage, the same excessive whereabout burrs, will lead to refrigerant leakage.

1.3, according to different pipe diameter size, the expansion is too large or too small are easy to be poor airtight performance, resulting in refrigerant leakage.

1.4, in order to ensure the cleanliness of the refrigerant tube internal, must be in the opening to do a timely sealing bandage, to prevent moisture and impurities into the air conditioning system, so as to avoid the expansion valve, capillary blockage, compressor wear caused by failure.

2, refrigerant pipe project

2.1. When welding copper pipe with the same diameter, the expansion tube should be carried out, not the opening. The quality of the expansion tube will directly affect the quality of welding.

3, refrigerant pipe ding

3.1, in order to avoid the production of oxides, welding must do nitrogen replacement, brazing can not be immediately with cold water for irrigation cooling, must let it cool naturally, so as not to cause cracks due to different expansion coefficients at the copper pipe connection, resulting in refrigerant leakage.

4, refrigerant pipe project

4.1, with decorative belt to the refrigerant tube wrap, pay attention to the insulation material combination can not leave gaps. In addition, in order to prevent rain infiltration, and ensure that the package in the refrigerant tube decoration is not easy to bond dust, should be wrapped from the bottom up.

5, refrigerant pipe project

5.1, the distance between the two adjacent support points of the refrigerant tube is less than 1.5 meters, such as the refrigerant pipe interval is too long, back causether refrigerant tube sagging, increase refrigerant flow resistance, so that the performance of air conditioning decreased, noise increased.

5.2, should ensure that the support part is strong, to avoid vibration in the course of operation, sagging off, and affect the effect of air conditioning.

6, drainage pipe project

6.1. Drainage pipe should maintain at least 1\/100 slope, may lead to poor drainage, condensate can not be discharged in time, and even from the indoor machine water tray overflow, damage decoration.

6.2, the distance between the two support points adjacent to the drainage pipe is less than or equal to 1 meter, and ensure that the support part is strong enough to avoid the generation of air bags, resulting in poor drainage.

6.3, horizontal drainage pipe must avoid hedging phenomenon, so as to avoid slope collapse and poor drainage.

7, drainage pipe project

7.1. A single-machine drainage connection shall be made to ensure smooth drainage.

7.2, must be drainage pipe leakage experiment, detection of drainage pipe leakage.

7.3, the connection part of the insulation material must overlap appropriately, the condensing water pipe through the locking clamp and the indoor machine firmly connected. Ensure that the insulation is tight, no condensation produced.

7.4, the highest point of the drainage pipe should be set up ventilation holes to ensure the smooth discharge of condensate, breathable holes must be facing down, to avoid dust and other debris into the blockage.

8, drainage pipe engineering

8.1, confirm the end of the drain age outlet position, pay attention not directly into the sewage pipe. Direct access to the sewage drainage pipe will cause odor in the water pipe into the indoor machine, resulting in a decrease in indoor air quality. At the same time, sewage pipe blockage will cause sewage reflux into the indoor machine, and even overflow from the indoor machine, damage decoration.

8.2. It is forbidden to be connected to the sewage pipe at the end of the condensate drainage pipe.

9, signal line engineering

9.1, signal line to use Y-type terminals and outdoor machine terminal connection, to ensure that the signal stable transmission.

9.2, signal line needs to be protected by PVC wire tube and plastic hose combination.

9.3, the signal shield ingress at both ends to ground, so as to shield the external and signal between the electronic interference.

10, power cord engineering

10.1 Power cord to use O-terminals and outdoor machine terminal connection, to ensure that the power cord connection is stable, to avoid poor contact.

Four, installation of outdoor machine, nitrogen-filled pressure, vacuum drying four, installation of outdoor machine, nitrogen-filled pressure- vacuum drying

1, outdoor machine placement

The installation of outdoor machine first to leave enough space for maintenance, and to ensure that the outdoor machine around the air flow is smooth, good cooling conditions. Avoid the device from not functioning properly due to poor cooling.

2, the fixed outdoor machine

2.1, at the bottom of the base should be laid shock-proof rubber mats to prevent vibration, reduce noise.

2.2, we must pay attention to the air-conditioning outdoor machine under the discharge of heating cream water, to avoid frost drops downstairs, resulting in neighborhood disputes.

3, nitrogen-filled pressure

3.1, in order to ensure the normal operation of the system, should be connected in the internal and external machine, nitrogen charge pressure. Nitrogen charge is used to confirm the pipe system no leakage inspection work, as well as the discovery of refrigerant pipe leakage point, timely repair.

3.2, the new refrigerant R410A product pressure than R22 product pressure.

4, vacuum drying

4.1, before filling the vacuum agent to the entire system to vacuum, in order to get out of the air and moisture, to ensure that the system is dry. Vacuum drying must use a vacuum pump and ensure sufficient time to prevent moisture and air residue from remaining in the pipe sending the system into operation.

4.2, Step 1: Drain the gas from the refrigerant tube. Bring the vacuum to -775mmHgn. Step 2: On this basis, continue to pump for 1 hour, the refrigerant tube may have water vapor extraction.

fifth. Nitrogen-filled refrigerants and refrigerant leak inspection, connecting power supply

1, fill the refrigerant

Refrigerant filling is carried out with refrigerant-filled meters to ensure reasonable refrigerant filling.

2, refrigerant leak inspection

Outdoor machine installation, must be outdoor machine, indoor machine refrigerant leakage, only to confirm that everything is normal, can continue to fill the nitrogen pressure, vacuum, filling refrigerant and other work.

3.1, in order to avoid refrigerant pipe damage in high temperature power line insulation, power cord can not be laid close to the media pipe, in order to avoid interference with the control signal, the power cord and signal line should generally maintain a distance of more than 50mm.

3.2, the power cord should be connected with the connection terminal and the connection bolt.

Relevant information- ·Factory electrical installation construction specifications

- ·Central air-conditioning insulation

- ·What are the key points of central air-conditioning scheme d

- ·How commercial central air conditioners work

- ·Central air-conditioning refrigeration unit conversion metho

- ·What problems should be paid attention to in the installatio

- ·Central air conditioning installation specification (i) - pr

- ·Central air conditioning installation specification (II) - c

- ·Central air conditioning installation specification (iii) -

- ·Dust-free purification engineering solutions

Top Categories in Cassette Fan coil unit types-KM

-

Water chilled Ceiling concealed 8 way Cassette Fan coil unit 300CFM -(FP-51KM)

Detailed Product DescriptionWater chilled Cassette Fan coil units KM s...

-

Water chilled Ceiling concealed 8 way Cassette Fan coil unit 400CFM -(FP-68KM)

Detailed Product DescriptionWater chilled Cassette Fan coil units KM s...

-

Water chilled Ceiling concealed 8 way Cassette Fan coil unit 500CFM -(FP-85KM)

Detailed Product DescriptionWater chilled Cassette Fan coil units KM s...

-

Water chilled Ceiling concealed 8 way Cassette Fan coil unit 500CFM -(FP-85KM)

Detailed Product DescriptionWater chilled Cassette Fan coil units KM s...

All Categories

- Water chilled Ceiling concealed 8 way Cassette Fan coil unit 300CFM -(...

- Water chilled Ceiling concealed 8 way Cassette Fan coil unit 400CFM -(...

- Water chilled Ceiling concealed 8 way Cassette Fan coil unit 500CFM -(...

- Water chilled Ceiling concealed 8 way Cassette Fan coil unit 500CFM -(...

- fan coil unit type-Cassette 800CFM -(FP-136KM)

- Water fan coil-(FP-170KM)

- Water chilled Ceiling concealed 8 way Cassette Fan coil unit 1200CFM -...

Top Categories in VRF Air conditioner-ODU

-

fabrica de China acondicionador de aire VRF | inversor de CC Fuera de unidades de puerta tipo modular| 168kw /60HP

Proveedor de China de acondicionador de aire VRF | inversor de CC Fuer...

-

fabrica de China de acondicionador de aire VRF | inversor de CC Fuera de unidades de puerta tipo modular|34HP 95KW

Proveedor de China de acondicionador de aire VRF | inversor de CC Fuer...

-

fabrica de China acondicionador de aire VRF | inversor de CC Fuera de unidades de puerta tipo modular| 184.5kw /66HP

Proveedor de China de acondicionador de aire VRF | inversor de CC Fuer...

-

fabrica de China acondicionador de aire VRF | inversor de CC Fuera de unidades de puerta tipo modular| 146.5kw /52HP

Proveedor de China de acondicionador de aire VRF | inversor de CC Fuer...

All Categories

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- VRF DC INVERTER AIR CONDITIONER Out door units

- VRF system with HITACHI compressor(DRV-56)

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- Proveedor de China de acondicionador de aire VRF | inversor de CC Fuer...

- Proveedor de China de acondicionador de aire VRF | inversor de CC Fuer...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- fabrica de China de acondicionador de aire VRF | inversor de CC Fuera ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

- fabrica de China acondicionador de aire VRF | inversor de CC Fuera de ...

Top Categories in VRF Air conditioner-IDU

-

China good quality VRF Unit factory| ceiling cassette type indoor unit | 16KW| 360° round way flow air outlet

DEKON VRF air conditioner China good quality VRF Factory for years.Dek...

-

VRF system indoor unit cassette type

Detailed Product DescriptionVRF air conditioner,with below features:1....

-

VRF system indoor unit wall type

Detailed Product DescriptionVRF air conditioner,with below features:1....

-

VRF system indoor unit ceiling concealed high pressure type

Detailed Product DescriptionDEKON VRF air conditioner,with below featu...

All Categories

- China good quality VRF Unit factory| ceiling cassette type indoor unit...

- VRF system indoor unit cassette type

- VRF system indoor unit wall type

- VRF system indoor unit ceiling concealed high pressure type

- VRF system indoor unit ceiling concealed mid pressure type

- VRF Air conditioner indoor unit ceiling floor type

- VRF Air conditioner indoor unit cassette type

- VRF air conditioner indoor unit ceiling floor type

- VRF Air conditioner indoor unit ceiling concealed type

- VRF air conditioner indoor unit ceiling floor type

- VRF air conditioner indoor unit ceiling concealed high pressure type

- VRF air conditioner indoor unit ceiling concealed slim design

- VRF air conditioner indoor unit cassette type

- VRF AIR CONDITIONER Out door units DC INVERTER technology

- VRF AIR CONDITIONER Out door units DC INVERTER technology

- EOT crane E house fitted High temperature AC

- VRF air conditioner indoor unit wall type

- VRF air conditioner cassette type indoor unit 2.8KW 360° air outlet ro...

- Dekon VRF air conditioner cassette type indoor unit 3.6KW 360° air out...

- Dekon VRF air conditioner cassette type indoor unit 4.5KW 360° air out...

- Dekon VRF air conditioner cassette type indoor unit 5.0KW 360° air out...

- Dekon VRF air conditioner cassette type indoor unit 5.6KW 360° air out...

- Dekon VRF air conditioner cassette type indoor unit 6.3KW 360° air out...

- China good quality VRF air conditioner|cassette type indoor unit | 240...

- China good quality VRF air conditioner supplier|cassette type indoor u...

- China good quality VRF air conditioner factory|cassette type indoor un...

- China good quality VRF Unit factory|cassette type indoor unit | 11.2KW...

- China good quality VRF Unit factory|cassette type indoor unit | 11.2KW...

Top Categories in Air cooled Chiller system

-

Air cooled water chiller screw type

Detailed Product Description unit style CMA200DNCooling capacitykW700I...

-

Air cooled chiller modular type with heat pump-20TR

Air cooled chiller modular chiller-20TRThe unit shell is made of galva...

-

Air cooled chiller modular type with heat pump-20TR

Air cooled chiller modular chiller-20TRThe unit shell is made of galva...

-

Air cooled chiller modular type with 122kw capacity-35TR scroll chiller

Detailed Product DescriptionAir cooled chiller modular type with 122kw...

All Categories

- Air cooled water chiller screw type

- Air cooled chiller modular type with heat pump-20TR

- Air cooled chiller modular type with heat pump-20TR

- Air cooled chiller modular type with 122kw capacity-35TR scroll chille...

- Air cooled screw chiller 200TR with heat pump optional(CMA200DN)

- Air cooled chiller screw type 200TR with heat pump (CMA200DN)

- Air cooled screw chiller 700KW with heat pump

- Air cooled chiller modular type with heat pump-40TR

- Air cooled screw chiller 1500KW-with heat pump optional

- Air cooled screw chiller 1120KW-with heat pump optional

- Air cooled screw chiller 930KW-with heat pump optional

- Air cooled screw chiller 840KW-with heat pump optional

- Air cooled screw chiller 560KW-with heat pump optional

- Air cooled screw chiller 740KW-with heat pump optional

- Air cooled screw chiller 370KW-with heat pump optional

- Air cooled screw chiller 700KW with heat pump

- Air cooled screw chiller 150TR

- Air cooled chiller screw type 200TR with heat pump (CMA200DN)

- Air cooled chiller screw type 100TR with R134a gas

- High efficiency screw compressor heat pump chiller

- R22 gas Air cooled chiller screw type 390TR with heat pump ASWC-HC390

- Air cooled heat pump-40TR

- Air cooled chiller modular chiller

- Air cooled chiller modular type with 122kw capacity- 122x4=130TR scrol...

- Air cooled screw chiller 200TR with R134A Gas

- Air cooled chiller modular chiller

- Bitzar compressor Air cooled screw chiller

- Bitzar compressor Air cooled screw chiller

Top Categories in Water cooled chiller system

-

Centrifugal water cooled chiller

Detailed Product Description LC Centrifugal water chiller:LC series of...

-

Water cooled chiller Centrifugal type for Nuclear Power Station

Detailed Product Description LC Centrifugal water chiller:LC series of...

-

Centrifugal Water cooled chiller

Detailed Product Description Water-cooled Screw Chiller Refrigerant: R...

-

Water cooled chiller Centrifugal type for Nuclear Power Station

Detailed Product Description LC Centrifugal water chiller:LC series of...

All Categories

- Centrifugal water cooled chiller

- Water cooled chiller Centrifugal type for Nuclear Power Station

- Centrifugal Water cooled chiller

- Water cooled chiller Centrifugal type for Nuclear Power Station

- Water cooled screw chiller

- low temperature Centrifugal water cooled chiller

- Centrifugal water chiller-twin compressor

- Twin compressor Centrifugal water chiller

- Centrifugal Chiller for Nuclear Power Station

- Centrifugal water Chiller for Nuclear Power Station

- Centrifugal water chiller

- Centrifugal water chille

- Twin compressor Centrifugal water cooled chiller

- Centrifugal water cooled chiller Twin compressor

- Centrifugal water cooled chiller

- Centrifugal water cooled Chiller for Nuclear Power Station

- Centrifugal water cooled Chiller for Nuclear Power Station

- Twin compressor Centrifugal water chiller

- Centrifugal water Chiller for Nuclear Power Station

- Centrifugal water Chiller for Nuclear Power Station

- Centrifugal water chiller

- Centrifugal water chiller Twin compressor

- Twin compressor Centrifugal water chiller

- Centrifugal Water chiller

- Twin compressor Centrifugal chiller

- Centrifugal water Chiller for Nuclear Power Station

- Centrifugal water Chiller for Nuclear Power Station

- Centrifugal water Chiller 2000TR capacity for T3 conditions

Top Categories in Cassette Fan coil unit types-E

-

Water chilled ceiling concealed Cassette Fan coil units 2 tubes 1200CFM-(FP-204CA-E)

Detailed Product Description model(2 tube system)FP-102CA-EFP-136CA-EF...

-

Water chilled ceiling concealed Cassette Fan coil units 2 tubes 1400CFM-(FP-238CA-E)

Detailed Product Description model(2 tube system)FP-102CA-EFP-136CA-EF...

-

Water chilled ceiling concealed Cassette Fan coil units 2 tubes 200CFM-(FP-34CA-E)

Detailed Product Description model(2 tube system)FP-34CA-EFP-51CA-EFP-...

-

Water chilled ceiling concealed Cassette Fan coil units 2 tubes 300CFM-(FP-51CA-E)

Detailed Product Description model(2 tube system)FP-34CA-EFP-51CA-EFP-...

All Categories

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 1200CF...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 1400CF...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 200CFM...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 300CFM...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 400CFM...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 500CFM...

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 200CFM...

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 300CFM...

- Fan coil unit type-cassette water fan coil(FP-68CA-E4)

- fan coil unit type-cassette four ways(FP-85CA-E4)c

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 800CFM...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 800CFM...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 1000CF...

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 600CFM...

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 1000CF...

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 1200CF...

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 1400CF...

- Water chilled Ceiling conceiled Cassette Fan coil units 4 tubes 1400CF...

- Water chilled ceiling concealed Cassette Fan coil units 2 tubes 600CFM...

Top Categories in Cassette Fan coil unit types-K

-

Four Way Cassette Type Fan Coil with DC Motor (FP-204CA/4KD)

Detailed Product DescriptionApplication:CommercialType:Fan Coil UnitFo...

-

Four Way Cassette Type Fan Coil with DC Motor (FP-238CA/4KD)

Detailed Product DescriptionApplication:CommercialType:Fan Coil UnitFo...

-

Four Way Cassette Type Fan Coil with DC Motor (FP-102CA/4KD)

Detailed Product DescriptionApplication:CommercialType:Fan Coil UnitFo...

-

DC Motor Four Way Cassette Fan Coil units(FP-85CA/4KD)

Detailed Product DescriptionApplication:CommercialType:Fan Coil UnitFo...

All Categories

- Four Way Cassette Type Fan Coil with DC Motor (FP-204CA/4KD)

- Four Way Cassette Type Fan Coil with DC Motor (FP-238CA/4KD)

- Four Way Cassette Type Fan Coil with DC Motor (FP-102CA/4KD)

- DC Motor Four Way Cassette Fan Coil units(FP-85CA/4KD)

- DC Motor Four Way Cassette Fan Coil units(FP-68CA/4KD)

- DC Motor Four Way Cassette Fan Coil units(FP-51CA/4KD)

- DC Motor Cassette Fan Coil units(FP-34CA/KD)

- DC Motor Cassette Fan Coil units(FP-51CA/KD)

- DC Motor Cassette Fan Coil units(FP-68CA/KD)

- DC Motor Cassette Fan Coil units(FP-85CA/KD)

- DC Motor four way Cassette Fan Coil units(FP-102CA/KD)

- DC Motor four way Cassette Fan Coil units(FP-136CA/KD)

- DC Motor four way Cassette Fan Coil units(FP-170CA/KD)

- DC Motor four way Cassette Fan Coil units(FP-204CA/KD)

Top Categories in Ceiling concealed-fan coil unit types

-

Ceiling concealed duct fan coil unit

Detailed Product DescriptionType:Central Air ConditionersCooling/Heati...

-

Ceiling concealed duct fan coil unit- 340CFM (2 tubes)

Detailed Product DescriptionType:Central Air ConditionersCooling/Heati...

-

Ceiling concealed duct fan coil unit- 510CFM (2 tubes)

Detailed Product DescriptionCooling/Heating:Cooling/HeatingCeiling con...

-

Ceiling concealed duct fan coil uint-680CFM (2 tubes)

Detailed Product DescriptionCooling/Heating:Cooling/HeatingCeiling con...

All Categories

- Ceiling concealed duct fan coil unit

- Ceiling concealed duct fan coil unit- 340CFM (2 tubes)

- Ceiling concealed duct fan coil unit- 510CFM (2 tubes)

- Ceiling concealed duct fan coil uint-680CFM (2 tubes)

- Ceiling concealed duct fan coil uint-680CFM (2 tubes)

- Ceiling concealed duct fan coil unit-850 CFM (2-TUBES)

- Ceiling concealed duct fan coil unit- 1020 CFM ( 2 tubes)

- Ceiling concealed duct fan coil unit-1360CFM (2 TUBES)

- Ceiling concealed duct fan coil unit- 1700CFM (2 TUBES)

- Ceiling concealed duct fan coil unit-2040CFM (2 TUBES)

- Ceiling concealed duct fan coil unit-2380CFM ( 2 tubes)

- Ceiling concealed duct fan coil unit-340CFM (4 tubes)

- Ceiling concealed duct fan coil unit-510CFM ( 4 tubes)

- Ceiling concealed duct fan coil unit-680CFM (4 tubes)

- Ceiling concealed duct fan coil unit-850 CFM (4 tubes)

- Ceiling concealed duct fan coil unit-1020CFM (4 tubes)

- Ceiling concealed duct fan coil-1360CFM (4 tubes)

- water fan coil-Ceiling concealed duct fan coil unit type-170CFM(4 tube...

- water fan coil-Ceiling concealed type-2040CFM (4 tubes)

- Fan Coil units with EC Motor(FP-85WA/E)

- Ceiling concealed Fan Coil units with EC Motor(FP-204WA/E)

- Ceiling concealed Fan Coil units with EC Motor(FP-238WA/E)

- Ceiling concealed Fan Coil units with EC Motor(FP-238WA/4E)

- Ceiling concealed Fan Coil units with EC Motor(FP-204WA/4E)

- EC Motor Ceiling concealed Fan Coil 4 pipe system (FP-170WA/4E)

- EC Motor Ceiling concealed Fan Coil with 4 pipe system (FP-68WA/4E)

- Fan Coil units with EC Motor 4 pipe system(FP-85WA/4E)

- Ceiling concealed Fan Coil units with EC Motor 4 pipe (FP-102WA/4E)

Top Categories in Ceiling floor fan coil unit types

-

One way cassette fan coil units-4tubes

Detailed Product DescriptionmodelFP-34O-4FP-51O-4FP-68O-4FP-85O-4power...

-

Ceiling floor type fan coil units 2 tubes 1200CFM-FP-204CF)

Detailed Product DescriptionPower (W):189Voltage (V):220Use:RoomPower ...

-

Ceiling floor type fan coil units 2 tubes 1000CFM-(FP-170CF)

Detailed Product DescriptionPower (W):152Voltage (V):220Use:RoomPower ...

-

Ceiling floor type fan coil units 2 tubes 800CFM-(FP-136CF)

Detailed Product DescriptionPower (W):134Voltage (V):220Use:RoomPower ...

All Categories

- One way cassette fan coil units-4tubes

- Ceiling floor type fan coil units 2 tubes 1200CFM-FP-204CF)

- Ceiling floor type fan coil units 2 tubes 1000CFM-(FP-170CF)

- Ceiling floor type fan coil units 2 tubes 800CFM-(FP-136CF)

- Water chilled Ceiling floor fan coil units 2 tubes 400CFM-FP-68CF

- Water chilled Ceiling floor fan coil units 2 tubes 500CFM-FP-85CF

- Water chilled Ceiling floor type fan coil units 2 tubes 1400CFM-(FP-23...

Top Categories in One way cassette fan coil unit types

-

Water chilled One way ceiling concealed cassette fan coil unit-FCU 200CFM-(FP-34O)

Detailed Product Description modelFP-34OFP-51OFP-68OFP-85Opower supply...

-

Water chilled One way ceiling concealed cassette fan coil unit-FCU 300CFM-(FP-51O)

Detailed Product Description modelFP-34OFP-51OFP-68OFP-85Opower supply...

-

Water chilled One way ceiling concealed cassette fan coil unit-FCU 400CFM-(FP-68O)

Detailed Product Description modelFP-34OFP-51OFP-68OFP-85Opower supply...

-

Water chilled One way ceiling concealed cassette fan coil unit-FCU 500CFM-(FP-68O)

Detailed Product Description modelFP-34OFP-51OFP-68OFP-85Opower supply...

All Categories

- Water chilled One way ceiling concealed cassette fan coil unit-FCU 200...

- Water chilled One way ceiling concealed cassette fan coil unit-FCU 300...

- Water chilled One way ceiling concealed cassette fan coil unit-FCU 400...

- Water chilled One way ceiling concealed cassette fan coil unit-FCU 500...

- Water chilled One way ceiling concealed cassette fan coil unit 4tube-F...

- Water chilled One way ceiling concealed cassette fan coil unit 4tube-F...

- fan coil unit type-cassette one way(FP-68O-4)

Top Categories in Universal Fan coil unit types

-

Water chilled Universal free stand type Fan coil units 1000CFM 4 TUBES-(FP-170U-4)

Detailed Product Description modelFP-102U-4FP-136U-4FP-170U-4FP-204U-4...

-

Water chilled Universal free stand type Fan coil units 1400CFM 4 TUBES-(FP-238U-4)

Detailed Product Description modelFP-102U-4FP-136U-4FP-170U-4FP-204U-4...

-

Water chilled Universal free stand type Fan coil units 1200CFM 4 TUBES-(FP-204U-4)

Detailed Product Description modelFP-102U-4FP-136U-4FP-170U-4FP-204U-4...

-

Water chilled Universal free stand type Fan coil units 800CFM 4 TUBES-(FP-136-4)

Detailed Product Description modelFP-102U-4FP-136U-4FP-170U-4FP-204U-4...

All Categories

- Water chilled Universal free stand type Fan coil units 1000CFM 4 TUBES...

- Water chilled Universal free stand type Fan coil units 1400CFM 4 TUBES...

- Water chilled Universal free stand type Fan coil units 1200CFM 4 TUBES...

- Water chilled Universal free stand type Fan coil units 800CFM 4 TUBES-...

- Water chilled Universal free stand type Fan coil units 600CFM 4 TUBES-...

- Water chilled Universal free stand type Fan coil units 300CFM-4 tubes(...

- Water chilled Universal free stand type Fan coil units 400CFM-4 tubes(...

- Water chilled Universal free stand type Fan coil units 500CFM-4 tubes(...

- Water chilled Universal free stand type Fan coil units 300CFM 2 TUBES-...

- Water chilled Universal free stand Fan coil units 400CFM 2 TUBES-(FP-6...

- Water chilled Universal free stand type Fan coil units 400CFM 2 TUBES-...

- Water chilled Universal free stand type Fan coil units 500CFM 2 TUBES-...

- Water chilled Universal stand type Fan coil units 200CFM-4 tubes(FP-34...

- Water chilled Universal stand type Fan coil units 200CFM 2 TUBES-(FP-3...

Top Categories in Wall split Fan coil unit types

-

High wall mounted type fan coil unti

Detailed Product DescriptionHigh wall fan coil unit in 2 tubes model(2...

-

Wall split type fan coil unit with valve inside

Detailed Product DescriptionHigh wall fan coil unit in 2 tubes with va...

-

water chilled high wall fan coil unit in 2 tubes

Detailed Product Descriptionwater chilled high wall fan coil unit in 2...

-

water fan coil

Detailed Product DescriptionWater fan coil- wall split typeWall split ...

All Categories

Top Categories in Light commercial A/C

-

CONSOLA PISO-TECHO Aire Acondicionado

Detailed Product Description CONSOLA PISO-TECHO AIRE ACONDICIONADO Ai...

-

CONSOLA PISO-TECHO TIPO

Detailed Product Description CONSOLA PISO-TECHO TIPO Aire Acondiciona...

-

aire acondicionado piso techo tipo

Detailed Product DescriptionUse:Aire Acondicionado Piso Techo TipoAire...

-

aire acondicionado piso techo tipo

Detailed Product DescriptionUse:Aire Acondicionado Piso TechoAire acon...

All Categories

Top Categories in Air handling Units

-

Equipos aires acondicionados de split ducto

Detailed Product DescriptionUse:Equipos Aires Acondicionados Split Duc...

-

Equipos aires acondicionados de split ducto

Detailed Product DescriptionUse:Equipos Aires AcondicionadosEquipos ai...

-

Equipos aires acondicionados de split ducto

Detailed Product DescriptionUse:Equipos Aires AcondicionadosEquipos ai...

-

Equipos aires acondicionados de split ducto

Detailed Product DescriptionUse:Equipos Aires AcondicionadosEquipos ai...

All Categories

- Equipos aires acondicionados de split ducto

- Equipos aires acondicionados de split ducto

- Equipos aires acondicionados de split ducto

- Equipos aires acondicionados de split ducto

- Equipos aires acondicionados de split ducto

- Suspendido en Techo horizontal UNIDADES MANEJADORAS DE AIRE (UMA)

- horizontal UNIDADES MANEJADORAS DE AIRE (UMA) Suspendido en Techo

- UNIDADES MANEJADORAS DE AIRE horizontal TIPO (UMA) Suspendido en Techo

- Suspendido en Techo horizontal decarga horizontal UNIDADES MANEJADORAS...

- horizontal UNIDADES MANEJADORAS DE AIRE (UMA)

- Vertical UNIDADES MANEJADORAS DE AIRE (UMA)

- Horizontal air handling units ceiling concealed type

- Modular design Air Handling Units-AHU for hospical

- Air handling units with prefilter and Hepa filter

Top Categories in Industrial Air conditioner

-

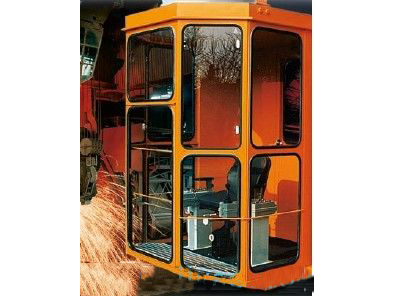

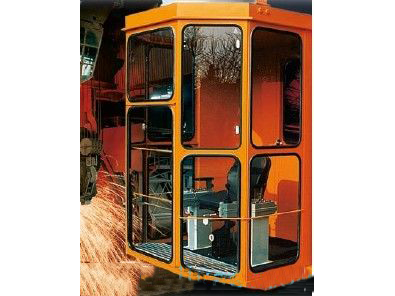

Coking plants high temperature air conditioner

Detailed Product Description In heavy industry field such as steel wor...

-

steel works high temperature air conditioner

Detailed Product Description In heavy industry field such as steel wor...

-

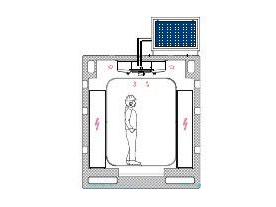

HIGH TEMPERATURE AC UNITS( AMBIENT TEMP 65C) FOR EOT CRANE APPLICATION

Detailed Product DescriptionHIGH TEMPERATURE AC UNITS( AMBIENT TEMP ...

-

HIGH TEMPERATURE Air conditioner FOR EOT CRANE APPLICATION

Detailed Product DescriptionHIGH TEMPERATURE AC UNITS( AMBIENT TEMP ...

All Categories